Wheeler lapping

Do you desire maximum accuracy, a strong connection between your riflescope and firearm, and also want to ensure that your expensive scope doesn’t suffer more than necessary during shooting? Lapping can help you with that.

In simplified terms, lapping refers to the very fine machining of materials using loose abrasive grains applied between the surfaces of the lapping tool and the lapped surface as they move against each other.

This operation is not unfamiliar to the gunsmithing trade, and in this article, we will focus on lapping scope mounting rings. With the right tools and at least basic skills, you can do it yourself. But what’s the benefit?

If the scope rings are not perfectly aligned on the same axis, the scope clamped andtightened in them is subjected to undesirable stress. The rings “pull” it towards a bend. Poor alignment also means that the rings do not contact the scope along their entire inner surface. Upon firing, the recoil can cause uneven stress on the scope tube, potentially leading to quicker wear, surface damage from the rings cutting into the scope’s finish, and reduced accuracy. Lapping can achieve perfect alignment of the rings, prevent all the aforementioned issues, and result in maximum accuracy.

Personally, I believe that the benefits of lapping are worth the little bit of effort and initial costs, especially if you identify with any of the arguments mentioned above.

Is it necessary?

It's a topic open for debate whether such an operation is really needed. The current uniformity in the manufacturing of scope bases and rings is at a high level,and this is often true even in lower-priced products. Most shooters can assemble them on their own without needing to resort to the expensive and time-consuming services of a gunsmith to correct any inaccuracies. Of course,it depends on the type of mounting, but if you purchase a rifle with a factory-installed one-piece Picatinny rail, even cheaper rings will provide more than sufficient accuracy for all "hunting" distances. A different situation may arise if we have split mounting bases and/or specialties, such as a detachable two-piece swing mount. There, there is more room for inaccuracies. Another consideration is the stress on the assembly, which comes from the cartridge's power and the weight of the scope. A small caliber and a lightweight scope (meaning less recoil energy and lower inertiaof the scope) will stress the mount less than a high-powered cartridge and a heavy "telescope." Another factor is the level of accuracy you wish to achieve. Is 1 MOA group size sufficient for you? Today, even inexpensive setups can achieve that without additional work. However, if you seek the highest possible accuracy, then lapping will help.

There is a claim that high-quality, expensive mounts do not need to be lapped. It can be said that as quality and price increase, so does the likelihood that lapping won’t be necessary, but this is by no means true in every case, as independent tests confirm. Furthermore, if you desire truly perfect alignment, then with the exception of high-quality mounts with a solid bridge connecting the rings, only lapping can guarantee it.

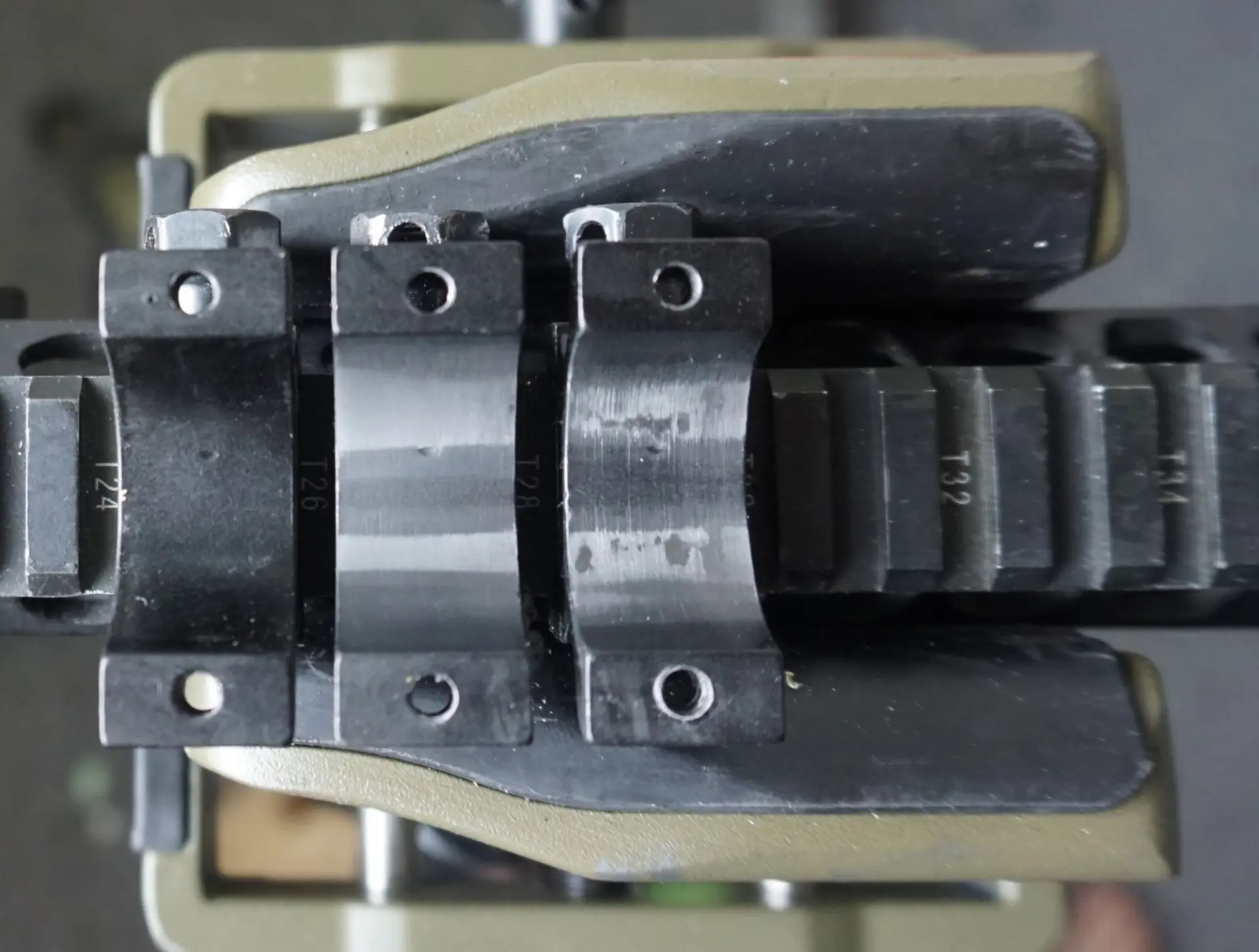

A compelling comparison of surface removal during lapping of inexpensive UTG rings (far left: non-lapped ring).

Applying lapping paste to the inner surface of the rings.

Wheeler Lapping

If you’vedecided to go ahead with lapping, you essentially have two options: either entrust your firearm to a gunsmith, or buy a lapping kit and do it yourself. Considering the cost and the demand for gunsmiths, it will cost almost the same, and the kit will last you nearly forever. It’s not rocket science, either, as long as you have basic skills and something to secure the firearm in.

We offer lapping kits from Wheeler Engineering, available either as a standalone set including a lapping rod, alignment rods, and lapping paste of a certain size, or as a larger set containing additional tools. On the following pages, we will introduce the larger kit and describe the entire lapping process step by step.

What does the kit include? The core of the kit is the lapping rod and a pair of alignment rods. We will describe their use shortly, but note that the diameter of the scope tube must correspond with the diameter of the rod. The kit includes the most common sizes, 25 mm and 30 mm, and you can also purchase the increasingly popular 34 mm size. Additionally, the kit contains lapping paste, thread-locking adhesive, a handle and adapter for handling the lapping rod, and a set of calibration levels. Also included is the FAT Wrench torque screwdriver. Proper tightening of the rings around the scope, the mounting base, and also the action to the stock can do wonders for the accuracy, strength, and durability of the assembly.

The set of bits includes the ten most common “Western” types, specifically hex keys in 3/32", 7/64", and 5/32", Torx T15 and T20, three sizes of flat heads, the proprietary "Leupold/Buehler windage bit," and a square adapter for larger bits with a head that can operate 12.4 mm hex nuts, which are often found on cheaper mounting rings, such as those from UTG. All of this comes in a nice plastic case with a clear manual.

The first step is to secure the rings or the mounting rings on the firearm. Make sure that the contact surfaces are clean. Then, properly secure the mount using the torque screwdriver (see box). Next, insert the pair of alignment rods into the rings with their points nearly touching each other. Then check the alignment of the points. If they align perfectly when viewed from above and the side, that’s ideal (though it doesn’t mean you should skip at least some light lapping). If, on the other hand, the points diverge slightly, then the rings definitely need lapping. It’s important to note that lapping is not a cure-all. If there’s a “step” of several millimeters between the points, something is either assembled incorrectly or manufactured poorly. In that case, only a return or a gunsmith can help, not lapping.

How to doit?

The actual process of lapping the rings is quite simple. Start by properly securing the rings with a torque screwdriver (see box) to the base, with the tops removed. Apply a thin but even layer of lapping compound to the inner surface of the rings where they contact the scope tube. A little goes a long way. Next, place the lapping rod into the rings. This is simply a steel rod with an outer diameter matching the desired scope tube, with a specific surface roughness and hardness. Then, lightly screw the tops of the rings back on. The rod should rotate around its axis with just slight resistance.

Next, you need to decide whether you want to lap manually or use a drill. For the first option, the kit includes a handle that attaches to the side of the rod; in the second case, you'll use the provided adapter to connect the drill head to the end of the rod. Hand lapping is a bit gentler, but a drill is faster, and if done carefully at low speed, there’s no reason not to take advantage of the machine’s power. During lapping, rotate the rod while simultaneously moving it back and forth. The lapping paste provides the abrasive action. Gradually and evenly tighten the ring screws while ensuring the rod continues to rotate with light resistance in the rings. I’ve found that using a torque wrench set to 5 in/lbs works well. After two or three minutes of work (you can tell the right moment when the rod rotates smoothly during lapping, but this is a skill that’s hard to put into words), remove the top part of the rings, thoroughly wipe the inner surfaces, and insert the alignment rods to check for alignment. If you’ve achieved alignment, the process is complete; if not, repeat the steps.

The next step is mounting the scope. The rings are still attached to the base. Remove the tops, take out the alignment rods, and place the scope in the rings. Then, carefully tighten the rings around the scope with the torque screwdriver to the desired torque (see box). It’s also a good idea to apply thread-locking adhesive to the screw threads before tightening them, which will add strength and prevent the screws from loosening due to recoil, but still allow for removal and retightening if necessary. If you have the large kit, the adhesive is included; otherwise, Loctite is commonly used. Personally, I’ve had good results with Loctite 243, though opinions on the best type may vary. However,it’s essential that the threads in the rings and on the screws are clean and degreased. I also caution against using any adhesive other than one specifically made for threads.

Hand lapping using a handle. Rotate the lapping rod while simultaneously moving it back and forth.

After lapping and aligning, tighten the scope using a torque screwdriver. It’s also advisable to use thread-locking adhesive.

Lapping using a drill attachment.

Alignment rods will reveal how aligned our rings are.

The standalone lapping kit, which includes the lapping rod, alignment rods, and lapping paste, costs 1.862 CZK and is available in sizes 25, 30, and 34 mm. A larger kit containing sizes 25 and 30 mm, along with the aforementioned accessories, costs 4.671 CZK. When you run out of paste (though this will take a long time, even if you were lapping for an entire club), you can purchase the original 30 ml package for 550 CZK, or you can get a common 220 grit paste, which is also offered by “civilian” manufacturers. All these kits, as well as other tools from Wheeler Engineering, can be purchased at STROBL.CZ s.r.o. More information can be found at strobl.cz or on the manufacturer's website, wheelertools.com.

Leveling the Scope

A standard procedure when mounting a scope should be to level it in relation to the firearm to avoid cant. If you’re shooting at a target 50 meters away, this can be done by eye, but for longer distances where we need to compensate for bullet drop, precise leveling using a bubble level is necessary. Otherwise, the point of impact may drift left or right as the distance changes. The larger Wheeler kit includes a set of two simple bubble levels specifically for this purpose. These can also be purchased separately, or you can buy a more precise version that comes with a dedicated slot in the case. We’ll bring you a separate review and instructions for this higher-end level in a future issue, but for now, we’ll focus on the level included in the kit.

The process is quite straightforward. First, secure the firearm in a vise or similar fixture. A regular vise lined with rags will work adequately with some care. Of course, a rotating vise makes the job easier. Find a horizontal flat surface on the firearm, usually the top of the receiver or the top of the mounting base. Place a level on it and adjust the firearm until the bubble is centered. Then insert the scope into the rings and tighten them just enough so that you can still rotate the scope within the rings with moderate resistance. Next, place the second, smaller bubble level on the vertical adjustment turret or its cap. The goal is to rotate the scope until the bubble is centered in both levels. Once aligned, evenly tighten the rings, check the levels one more time, and you’re done.

Leveling the scope using bubble levels.

Using a Torque Wrench

As mentioned earlier, properly tightening the rings around the scope, the base, and the action to the stock is highly desirable. It shouldn’t be overtightened ("on the blood") nor too loose. In the first case, the screws might loosen, causing the scope to shift; in the second, the scope or screw heads might get damaged, and accuracy could suffer in both cases. From personal experience, I can say that while this may seem minor, it’s definitely noticeable on the target. To achieve optimal tightening, you will need a good quality torque wrench with adjustable resistance and the appropriate bits. Insert the bit into the wrench, set the desired torque, and proceed with tightening.

What values should you choose? Most manufacturers provide this information in the accompanying documentation. In my case, Vortex printed the values directly on the rings. If you cannot find the recommended torque values for your rings, a general guideline is 35 in/lbs for the screws that attach the rings to the base, 20 in/lbs for the screws clamping the scope tube, and 25 in/lbs for the screws between the base and the action. For screws connecting the action to the stock, if you have metal bedding, the standard is 65 in/lbs. If not, 25-45in/lbs depending on the manufacturer. Browsing foreign shooting forums can also be helpful in this case.

It's not a bad idea to take the torque wrench to the range for the first sighting-in and retighten the screws to the specified values after shooting. It may happen that the screws need to “settle” a bit initially.

In conclusion, it’s worth noting that the tightening torque is usually specified in in/lbs, but other units, such as N-m, might also be used. It’s important to check this in advance and convert if necessary.

When mounting a scope, it’s advisable to use a torque wrench. Your setup will reward you with accuracy, durability, and reduced stress on the scope.

Photo Sources: Author's Archive

Article Author: Tomáš Prachař

The article originally appeared in the magazine Lovec by Extra Publishing.